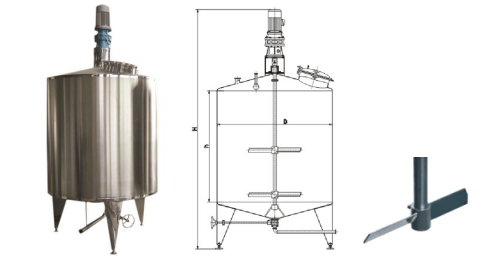

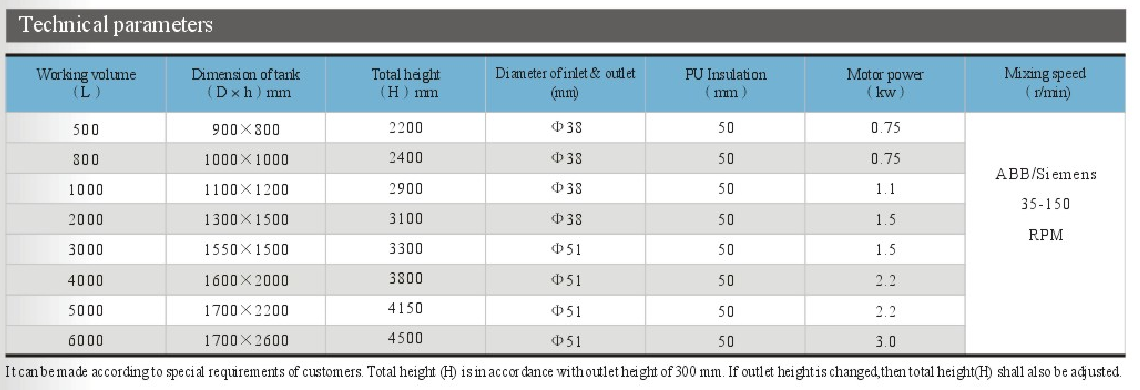

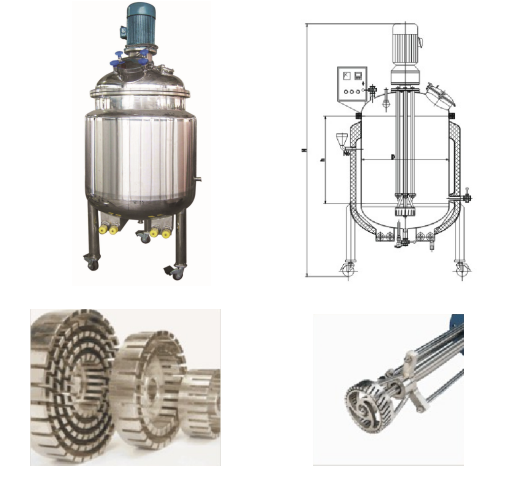

1. Single layer mixing tank: paddle agitator

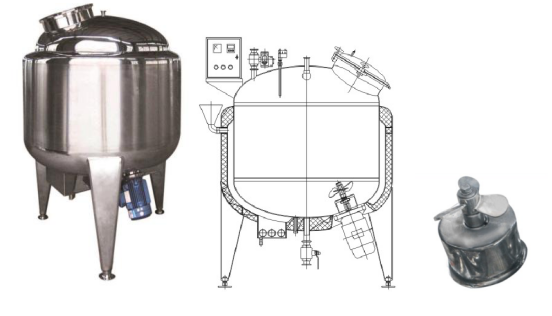

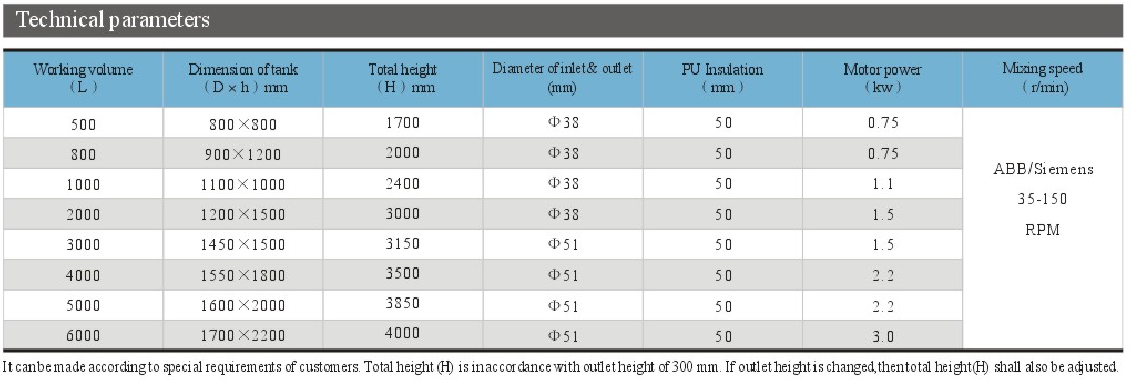

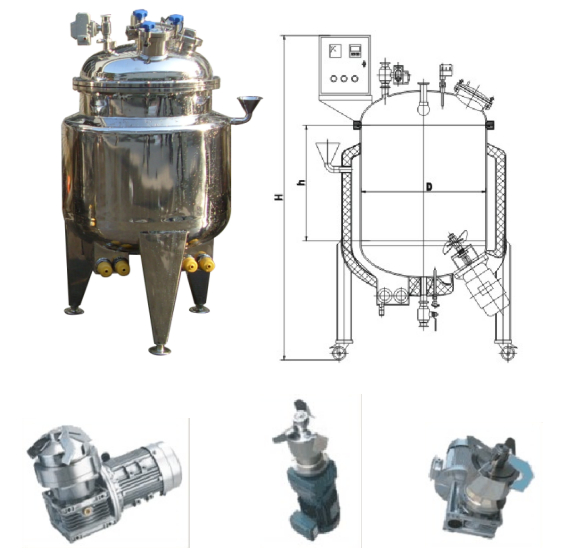

2. Three-layer bottom push-type mixing tank

3. Three-layer electric heating emulsification tank

4. Three-layer anchored mixing tank

5. Small electric heating magnetic stirring tank

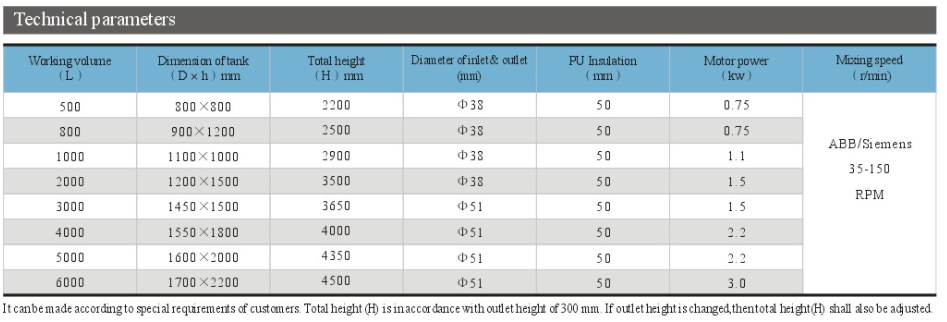

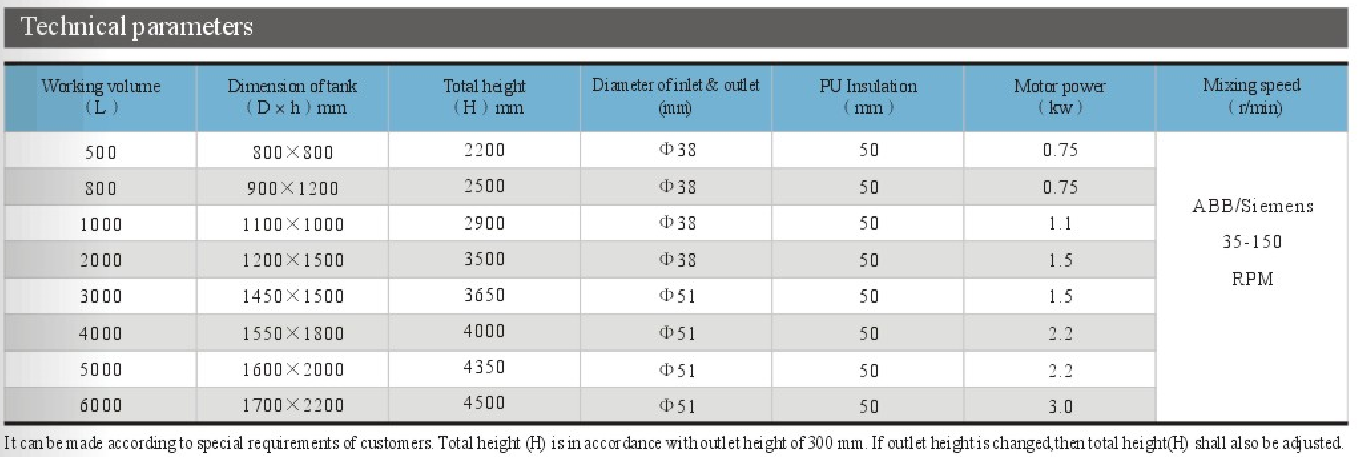

The function of the mixing tank can be divided into mixing, mixing, reconciling, homogenizing, etc. The stainless steel mixing tank can be standardized and humanized according to the requirements of the production process. Stirring tanks are widely used in coatings, medicine, building materials, chemicals, pigments, resins, food, scientific research and other industries. The equipment can be made of stainless steel and other materials according to the process requirements of the user's product, and be equipped with heating and cooling devices to meet different process and production needs. Heating forms include jacket electric heating, coil heating, and honeycomb panel heating. The equipment has reasonable structure design, advanced technology, long-lasting durability, simple operation and convenient use. It is ideal for low investment, fast production, and high return. Chemical Equipment. The mixing tank can realize feeding control, discharging control, mixing control and other manual and automatic control during the mixing process.

The structure of the mixing tank: mixing tank body, mixing tank cover, agitator, support, transmission device, shaft sealing device, etc., and heating device or cooling device can also be configured according to process requirements.

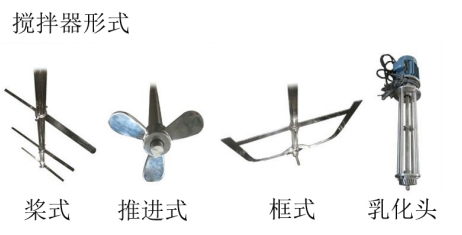

Materials such as mixing tank body, mixing tank cover, agitator and shaft seal can be made of stainless steel and other materials according to different process requirements. The mixing tank body and the mixing tank cover can be connected by flange sealing or welding. The mixing tank body and the mixing tank cover can be opened according to the process requirements, such as feeding, discharging, observation, temperature measurement, pressure measurement, steam fractionation, and safe venting. The upper part of the mixing tank cover is equipped with a transmission device (motor or reducer), and the agitator in the mixing tank is driven by the transmission shaft. The shaft sealing device can adopt various forms such as mechanical seal or packing, labyrinth seal (determined according to user needs). Due to the different production process requirements of users, the agitator can be equipped with various forms such as paddle type, anchor type, frame type and spiral type. If you have other requirements, please contact our factory to design and produce separately.

Structure:

Adopt the structure of inner cylinder and outer cover, and filled with heat preservation material in the middle.

The materials are all sanitary stainless steel.

The structure design is very humane, and it can be operated.

The transition section of the inner wall of the cylinder adopts arc transition to ensure sanitation and no dead corners.

Paddle mixing tank

Device Configuration:

Volume: 1BBL~100BBL

Material SS304

Tank body: single layer, double layer: liner + jacket Three layers: liner + jacket + heat preservation (outsourcing)

Polishing: mirror inside, matte outside / pickling inside, wire drawing outside

Accessories:

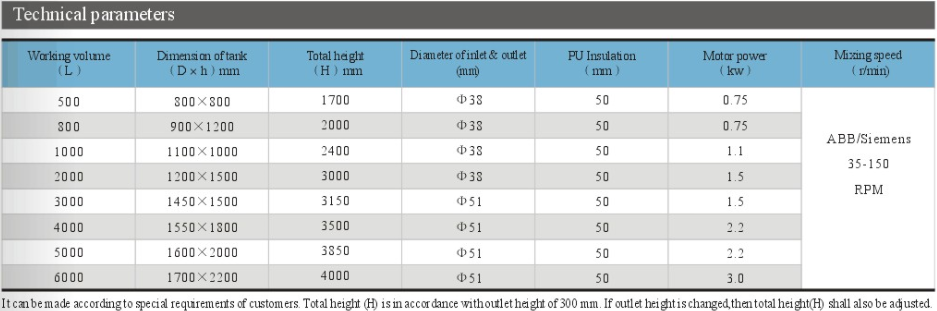

ABB or Siemens motor

Quick opening hole

Various types of CIP cleaners

Anti-fly and insect sanitary breathable cover

Adjustable triangle legs

Detachable feed tube kit

Thermometer (can be configured according to the requirements of each household)

Ladder (according to customer requirements) vertical agitator (can be configured according to customer requirements paddle type or frame type)

Anti-vortex plate

Vertical mixing

Polyurethane insulation

Reducer

Optional: sight glass, sight light, level gauge