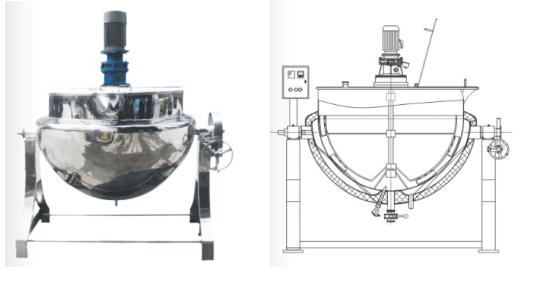

Jacketed pot is also known as steam pot, cooking pot, and jacketed steam pot. Usually composed of a pot body and a bracket, a worm wheel, and a worm. The pot body is a double-layer structure composed of an inner and an outer spherical pot body, with fixed, tiltable, stirring and other styles. Generally, the tiltable design volume will not exceed 600L, and the excess is basically fixed.

The equipment adopts an open-mouth condensable design, mainly for the decoction and concentration of liquid materials in the pharmaceutical, food, chemical, light industry and other industries.

The part of the equipment in contact with the material is made of stainless steel, which has good corrosion resistance, is durable and meets GMP requirements. At the same time, a stirring device can be added according to customer requirements.

way to heat up:

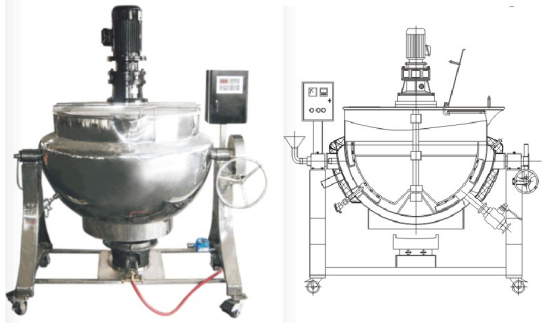

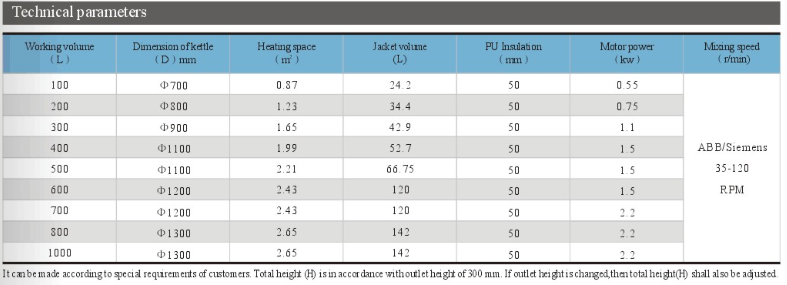

1) Gas heating

1. Specifications

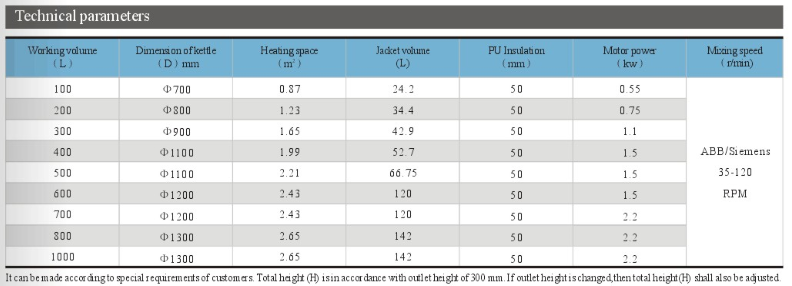

Volume 100L-1000L

Material Ss304 or Ss316L

Top opening

2. Thickness

Pot body 3mm

Jacket 3mm

Outsourcing 3mm

Insulation 50mm. Polyurethane

3. Stir

Propeller mixing 380v, 3ph, 50Hz, ABB or Siemens motor with reducer

4. Accessories

Thermometer probe, control cabinet, ball valve, etc.

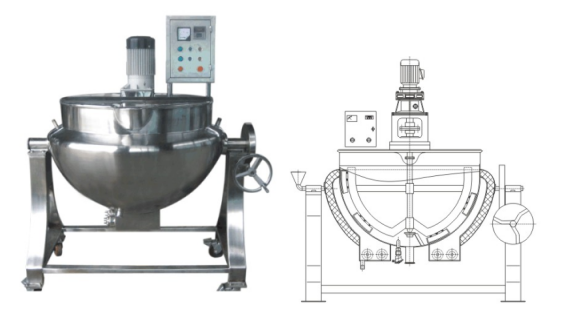

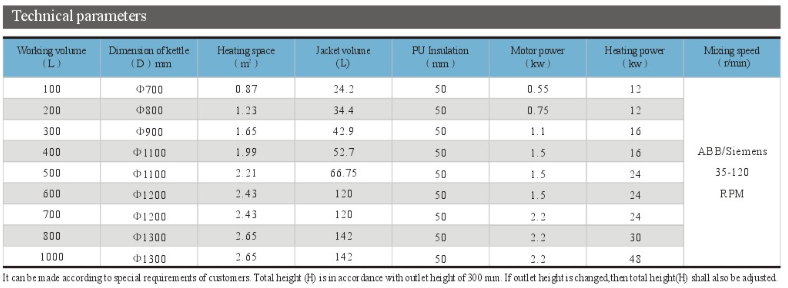

2) Electric heating

1. Specifications

Volume 100L-1000L

Material Ss304 or Ss316L

Top opening

2. Thickness

Pot body 5mm

Jacket 4mm

Outsourcing 3mm

Insulation 50mm polyurethane

3. Stir

Anchor mixing 380v, 3ph, 50Hz, ABB or Siemens motor with reducer

4. Accessories

Electric heating tube, thermometer probe, control cabinet, ball valve, etc.

3) Steam heating

1. Specifications

Volume 100L-1000L

Material Ss304 or Ss316L

Top opening

2. Thickness

Pot 6mm

Jacket 4mm

Outsourcing 3mm

Insulation 50mm asbestos

3. Stir

Frame type stirring with PTFE scraper 380v, 3ph, 50Hz, ABB or Siemens motor with reducer

4. Accessories

Thermometer probe, control cabinet, ball valve, etc.