The vacuum concentration system is suitable for the concentration of liquid materials such as traditional Chinese medicine, western medicine, food, MSG, dairy products, glucose, starch, fruit juice, and chemicals.

Features:

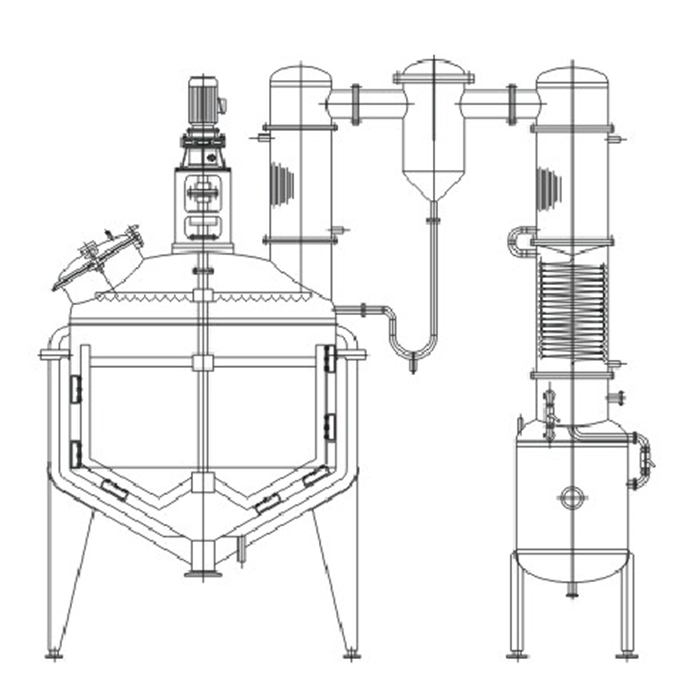

The scraper concentrator is mainly composed of the main concentrator tank with stirring device, the No. 1 condenser, the separator, the No. 2 condenser, the cooler, and the recovery tank. This product has novel design and unique structure. The scraper blade and the tank can be matched with spherical (GNQ) or conical (GNZ). It adopts jacket heating, stirring and evaporation, and the concentration effect is good. It is suitable for heat transfer, evaporation and concentration of high-viscosity materials, with a concentration of more than 1.4.

Structure:

Adopt the structure of inner cylinder and outer cover, and filled with heat preservation material in the middle.

The materials are all sanitary stainless steel.

The structure design is very humane, and it can be operated.

The transition section of the inner wall of the cylinder adopts arc transition to ensure sanitation and no dead corners.

Jar structure:

1. Concentrator main tank

Vacuum device

ABB or Siemens motor

Quick opening hole

Various types of CIP cleaners

Anti-fly and insect sanitary breathable cover

Adjustable triangle legs

Detachable feed tube kit

Steam material outlet

Thermometer (can be configured according to the requirements of each household)

Ladder (according to customer requirements) vertical agitator (can be configured according to customer requirements paddle type or frame type)

Condenser 2.1

Material listing

Cooling water inlet and outlet device

3. Separator

Condenser 4.2

Material listing

Cooling water inlet and outlet device

5. Cooler

Internal coil

Cooling water inlet and outlet device

6. Recycling tank

glass

Material export

Other configuration:

Vacuum pump

Water pump